Melody High Speed Steel Co8 Metal Drill Bit MLD-CHDB

WhatsApp us

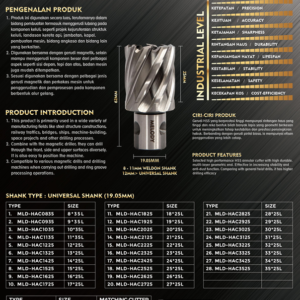

PRODUCT INTRODUCTION

- M42 is mainly used to processed high hardness materials , including high tension steel , stainless steel , superalloy , titanium alloy , carbon fibre composite material , aluminium , mould steel , mould copper and more

- Can be used with hand-held drill of drilling machine to perform multi-directional drillings that include surface , side and botton

PRODUCT FEATURE

-

- Selected quality high-speed steel m42 with 8% cobalt is manufactured strictly following DIN388 germany standard by using full-grindingtechnique

- it has a 135 bit-tip , h8 tolerance , and a cut-off point design following DIN 1412C .

- Comparing with general HSS drilling , M42 possesses higher red hardness , precision , wear-resistance , cutting force , fix-point stability , and impact durability

- Selected quality high-speed steel m42 with 8% cobalt is manufactured strictly following DIN388 germany standard by using full-grindingtechnique

| SIZE | WORKING LENGTH | TOTAL LENGTH |

| 1.0MM | 12MM | 34MM |

| 1.5MM | 20MM | 43MM |

| 2.0MM | 24MM | 49MM |

| 2.5MM | 30MM | 57MM |

| 3.0MM | 33MM | 61MM |

| 3.2MM | 36MM | 65MM |

| 3.3MM | 36MM | 65MM |

| 3.5MM | 39MM | 70MM |

| 4.0MM | 43MM | 75MM |

| 4.1MM | 43MM | 75MM |

| 4.2MM | 43MM | 75MM |

| 4.5MM | 47MM | 80MM |

| 4.8MM | 52MM | 86MM |

| 5.0MM | 52MM | 86MM |

| 5.1MM | 52MM | 86MM |

| 5.2MM | 52MM | 86MM |

| 5.5MM | 57MM | 93MM |

| 6.0MM | 57MM | 93MM |

| 6.5MM | 63MM | 101MM |

| 6.8MM | 69MM | 109MM |

| 7.0MM | 69MM | 109MM |

| 7.5MM | 69MM | 109MM |

| 8.0MM | 75MM | 117MM |

| 8.5MM | 75MM | 117MM |

| 9.0MM | 81MM | 125MM |

| 9.5MM | 81MM | 125MM |

| 10.0MM | 87MM | 133MM |

| 10.2MM | 87MM | 133MM |

| 10.5MM | 87MM | 133MM |

| 11.0MM | 94MM | 142MM |

| 11.5MM | 94MM | 142MM |

| 12.0MM | 101MM | 151MM |

| 12.5MM | 101MM | 151MM |

| 13.0MM | 101MM | 151MM |